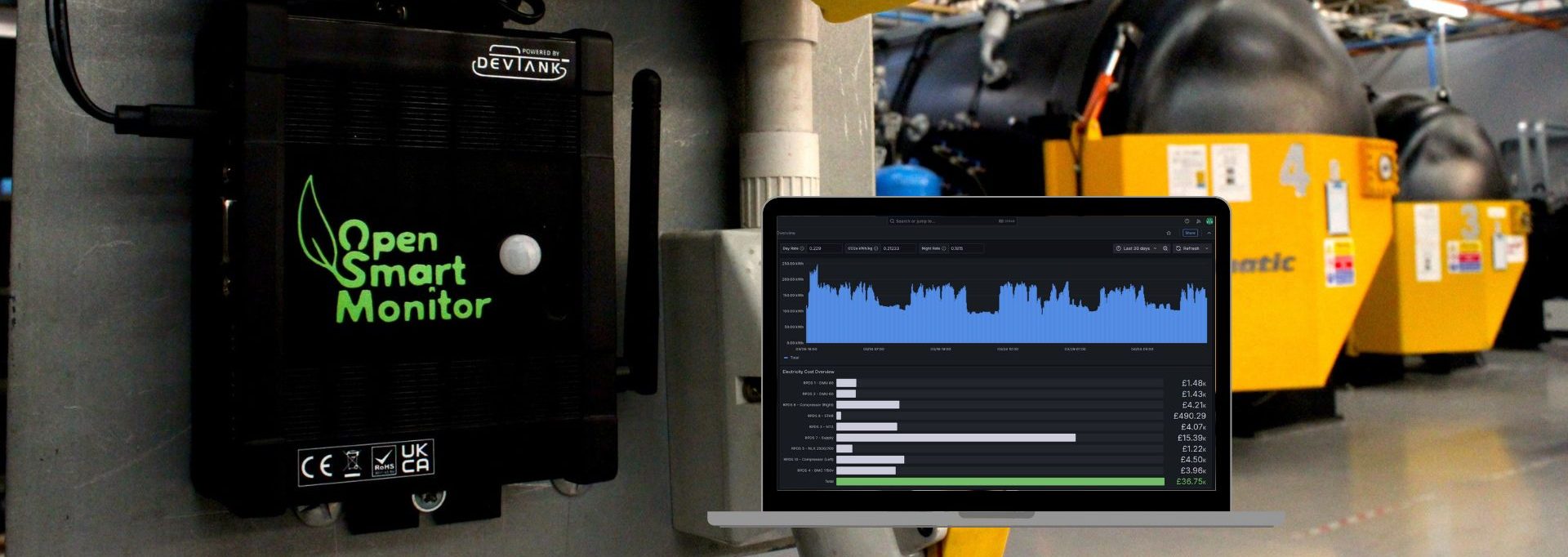

What is OpenSmartMonitor?

OpenSmartMonitor is our ready-to-go, plug-and-play, smart monitoring solution. Being crowned the Swiss Army knife of remote monitoring solutions, our sensor devices can monitor up to 20 parameters. Focusing on the three aspects of any business: Utilities, Environment, and Machinery, our system covers all key areas. Paired with our visual dashboard and automated alerting system, you gain key insights into your costs, efficiencies, emissions, and productivity. Through these insights, you will be able to drill down into areas where improvements can be found and made to reduce energy usage, costs, and improve emissions and productivity.

Electricity

Remote monitoring of your incoming supply revealing your usage, waste, carbon emissions, and costs. Add on a power profiler to include power factory measurements to find out what you are actually using compared to what you pay for.

Water/Gas

Remote monitoring of water and gas requires a pulse or flow meter to be installed prior to our system. Once installed and setup, OpenSmartMonitor will tell you your flow rates, usage, waste, costs, and alert you to potential leaks.

Why?

Environmental monitoring is key to maintaining and improving your workplace safety, compliance, and well-being. Do you know how dirty your air quality may be? Or how temperature and humidity could be affecting your staff and products?

Air quality

Measuring PM1, 2.5, 4, and 10 Microns, you will see where improved ventilation or PPE is required. With the added bonus of automated alerting, you will always stay ahead of environmental issues before they cause harm.

Temperature and Humidity

Temperature and humidity is key to improving productivity levels as well as well-being and product quality. It is recommended for a room to be no colder than 14 degrees C with humidity sitting between 40% and 60%. A poorly maintained level can cause fatigue and headaches to form amongst the work force, as well as product (especially wood, metals, and fabrics) becoming warped, bowed, or even expanding causing quality issues.

Sound Monitoring

Sound levels (dB) are a major topic when it comes to PPE use and health and safety. Being able to see when noise levels grow above the normal will ensure you comply with HSE ruling. Between 75 and 85dB will require PPE consideration, where about this PPE is a must.

Current Monitoring

Seeing how much it costs to run a machine or produce a product is key to maximizing your profitability and improving upon your process. Current monitoring will also indicate inefficiencies within machinery as well as potential break down reasons.

Vibration

Measuring the vibration of a machine or bearings of a machine will show you what a normal day looks like compared to when that machine is in need of maintenance. If your machinery vibration levels increase, this could be a sign that a bearing needs some love or a replacement, a belt is worn, or oil is drying out.

Temperature

Being able to see which machine is generating the most heat can help you improve your workplace heat dispersion which can lead to a major gas usage reduction. However, monitoring temperature on a machine is key to knowing when a machine could overheat and breakdown.

The Features of OpenSmartMonitor?

How It Works

- - Connect to your WiFi

- - Install and power on

- - Your data will then be collected and stored in the cloud

- - The cloud will then send this data to our visual dashboard