HILTOP is Devtank’s open source test and measurement platform designed to deliver reliable, scalable, and cost effective solutions for modern electronics and embedded product manufacturing. At its heart, HILTOP brings together modular hardware, open-source software, and decades of engineering expertise to create a flexible system that adapts to the needs of low-volume prototyping through to high volume production environments. It is widely deployed for PCB assembly verification, electric vehicle supply equipment (EVSE) testing, functional product validation, and bespoke end-of-line systems, ensuring manufacturers can meet stringent quality and compliance requirements without the burden of proprietary systems.

The platform was created to address a common challenge faced by manufacturers and test engineers: the need for a test system that is powerful yet flexible enough to evolve with changing products, markets, and production demands. Traditional closed test platforms can quickly become obsolete or cost-prohibitive, especially when dealing with new product introductions or custom functional requirements. By contrast, HILTOP is built around an open-source architecture powered by the Raspberry Pi Compute Module 4, Devtank’s OpenVTI, and software suite. This combination provides an affordable yet high-performance foundation that can be tailored for applications ranging from simple PCB bed of nails test fixtures to complex EVSE end-of-line testers.

A major strength of the HILTOP platform is its adaptability across testing scenarios. For board-level and circuit board testing, HILTOP supports both in-circuit and functional test methods through custom PCB test fixtures. Bed of nails test jigs can be designed and manufactured to match the exact pad layouts of a customer’s board, enabling rapid, repeatable, and accurate measurement of signals, voltages, and communication buses. This ensures complete verification of PCB assemblies before they move further down the production line, improving yield rates and reducing field failures. PCBA test fixtures are equally well supported, with options for in-system programming, boundary scan, and integration of additional functional checks such as LED illumination, button actuation, or sensor verification.

Beyond board-level applications, HILTOP has become a leading choice for EVSE testing. The demand for robust and compliant EV charger testers has grown rapidly as the adoption of electric vehicles accelerates globally. Testing electric vehicle charging stations is not limited to verifying simple connectivity; it requires full simulation of a vehicle connection, verification of charging protocols, load testing under varying conditions, and monitoring of safety features such as ground fault detection. HILTOP EVSE testers are designed to perform these tasks consistently and at scale. They can validate compliance with international standards such as IEC 61851 and ISO 15118, ensuring that domestic, commercial, and fast-charging products meet the rigorous demands of regulators and consumers alike. Whether deployed as a bespoke end-of-line tester for high-volume EVSE manufacturing or as a low-volume solution for pilot production runs, HILTOP ensures that every charger leaving the factory has been proven to perform safely and reliably.

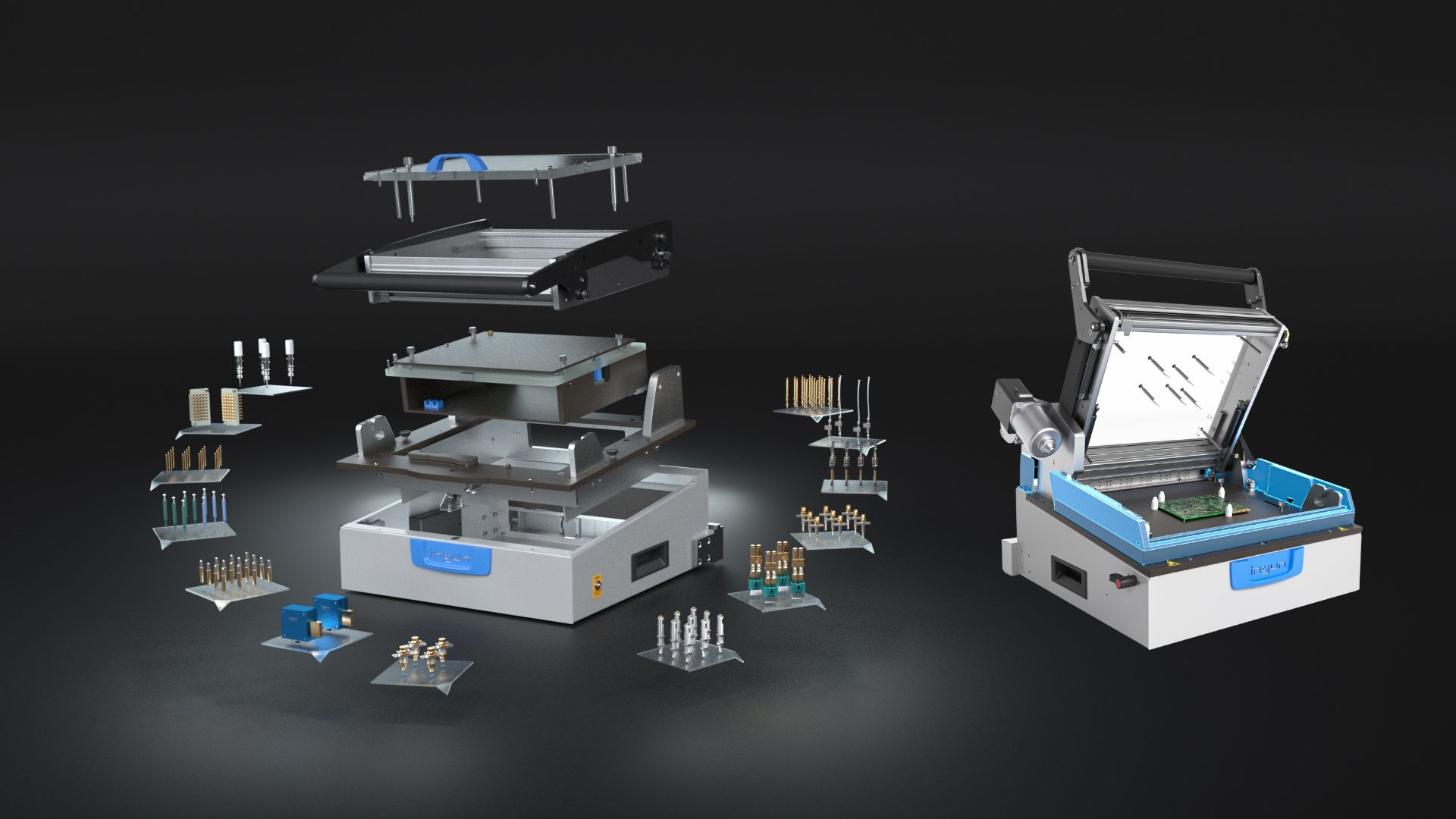

The modular hardware architecture of HILTOP allows it to be customised to suit each customer’s exact requirements. Interchangeable plugin cards, custom I/O interfaces, and optional modules for power measurement, relay switching, or RF testing can be combined to create tailored solutions without having to redesign the entire platform for each new project. This reduces both cost and lead time, while enabling manufacturers to reuse large parts of their test infrastructure across multiple product generations. Fixtures for low-volume production can be designed to incorporate 3D-printed DUT holders, vacuum lids, or press-fit assemblies, providing a robust yet cost-effective solution for new product introductions. At the other end of the scale, high-volume production lines benefit from barcode-driven automation, data logging, and fail/pass indication systems that ensure traceability and minimise operator error.

An important element of HILTOP’s appeal is OpenVTI, the open-source verification and test infrastructure developed by Devtank. This Linux-based software suite allows engineers to define, automate, and monitor their testing processes with complete transparency. Test routines can be written and modified without vendor restrictions, data can be logged and exported in standard formats such as CSV, JSON, or SQL, and the system can be integrated with existing manufacturing execution systems (MES) or enterprise resource planning (ERP) tools. This level of openness empowers companies to maintain control of their own testing workflows, adapt quickly to design changes, and ensure that the platform can evolve alongside their products.

In practice, HILTOP fixtures and systems are already deployed across a range of industries. In the telecom sector, the platform is used for functional testing of RF modules and network devices, ensuring that each board meets strict performance requirements before being deployed in the field. Aerospace and defence organisations rely on custom functional test fixtures to validate mission-critical hardware, where reliability and repeatability are non-negotiable. IoT device manufacturers benefit from low-volume test fixtures that are cost-effective during prototyping stages but designed to be scalable into volume testing as demand grows. In the automotive sector, HILTOP has become synonymous with reliable EVSE testing, offering some of the best EV charger testers available for AC wall boxes, DC fast chargers, and on-board vehicle adapters.

The flexibility of the HILTOP platform also ensures that investment in low-volume test solutions is not wasted. Early-stage prototypes can be validated using simple fixtures that later form the basis of volume test platforms. Reusable fixture bases, modular plugin cards, and configurable software mean that a test setup can be adapted for new revisions or entirely new products with minimal additional cost. This approach is particularly beneficial for start-ups or companies launching innovative new technologies, where production volumes may begin modestly but are expected to scale rapidly once market demand is proven.

By combining complete test solutions with industry-proven reliability, HILTOP eliminates the need for fragmented or piecemeal testing setups. Each fixture is designed with operator safety, ease of maintenance, and longevity in mind. With integrated barcode readers, label printers, and pass/fail indicators, fixtures can support modern lean manufacturing environments where efficiency and traceability are key. Engineers and operators alike benefit from systems that are intuitive to use yet powerful enough to capture detailed diagnostics when needed. The result is a test infrastructure that reduces costs, increases throughput, and provides the peace of mind that products leaving the production line are thoroughly validated.

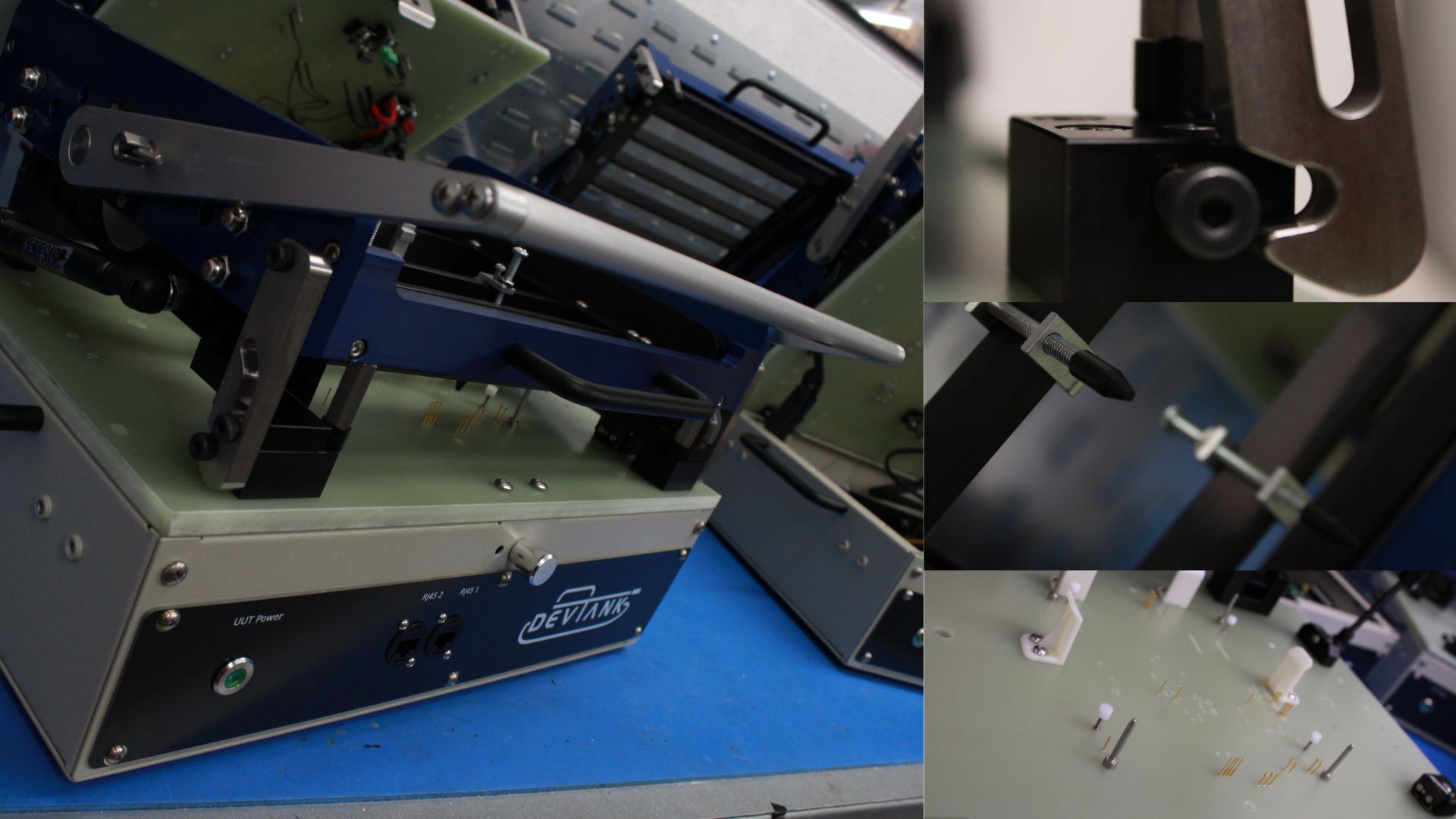

From a technical perspective, HILTOP test fixtures often incorporate features such as mechanical actuation for pogo-pin engagement, environmental sensors, custom cabling harnesses, and integrated communication interfaces including USB, Ethernet, CAN, or RS485. Fixtures designed for board-level test may include provisions for in-circuit programming, firmware flashing, or functional verification, while finished product testers can be equipped with high-current load simulation, touchscreen operation, and automatic report generation. These capabilities allow customers to perform everything from basic continuity checks through to complex system validation within a unified platform.

The emphasis on modularity and openness also extends to mechanical design. Devtank collaborates with partners such as INGUN and CODA-PIN to supply high-quality mechanical interfaces, ensuring that each bed of nails tester or PCB fixture achieves the precision and durability required for thousands of test cycles. Combined with Devtank’s in-house design expertise, these fixtures can be tailored to match unusual board geometries, delicate components, or products with unique housing requirements. By balancing robust mechanical design with flexible electronic control, HILTOP fixtures deliver both accuracy and repeatability.

Data-driven manufacturing is another area where HILTOP excels. Every test cycle can be logged with detailed metadata, including operator ID, timestamp, serial number, and pass/fail status. For high-volume environments, this ensures full traceability and the ability to identify process trends, yield issues, or recurring faults. For regulated industries such as automotive and aerospace, such traceability is essential for demonstrating compliance and ensuring accountability. OpenVTI’s capability to integrate with third-party data systems further strengthens this advantage, allowing companies to centralise their quality data and streamline reporting.

Ultimately, the HILTOP platform demonstrates that modern test solutions do not have to be expensive, proprietary, or inflexible. By focusing on open-source principles, modular hardware, and customisable fixtures, Devtank has created a system that supports every stage of the product lifecycle, from early prototyping through to high-volume production. Whether the requirement is a custom PCB fixture, a bespoke EVSE end-of-line tester, or a circuit board test fixture for low-volume runs, HILTOP offers a proven foundation for reliable, scalable, and transparent testing.

Production Test Solutions

HILTOP covers everything production testing, with the HILTOP itself being a comprehensive industrial test computer with capabilities to run a wide range of tests. Paired with a test fixture, HILTOP is the ideal production test solution, being simple, modular, and cost effective.

Why Production Test?

Improve Quality

Improve quality by identifying design flaws and component faults.

Improved Processes

Improve your processes with data driven insights and get it right 1st time.

Reduce Waste

Quality testing will reduce product defects and warranty returns.

Reduce Costs

Reduce time through automation and repeatable measurements.

The Features of HILTOP Test Solutions

Our Test Fixture Partners

We have proudly joined forces with two of the best test fixture manufacturers in the UK to bring you complete test solutions, from computer and software, to the physical test system. We receive a blank canvas and customise each fixture to your requirements.